Is your car’s engine making an unsettling knocking sound? If so, you might be experiencing the dreaded rod knock. This mechanical issue can strike fear into the hearts of even the most seasoned drivers. But fear not! In this blog post, we will explore the causes of rod knock and discuss how to extend life of an engine with rod knock problem. So buckle up and get ready to learn some valuable tips on keeping your engine running smoothly, even with a rod knock!

Causes of rod knock

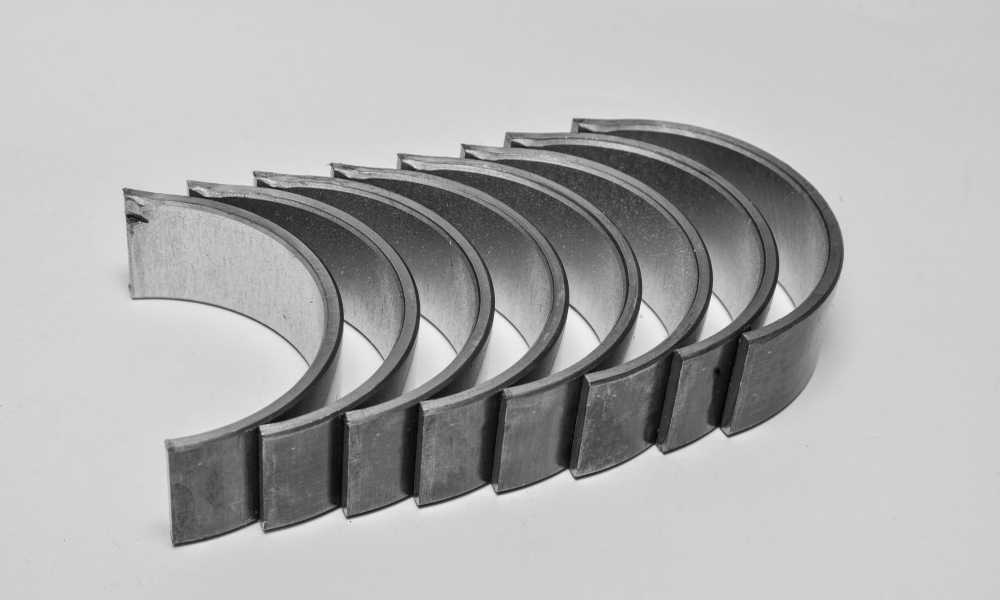

1. Worn bearings

The bearings, which are located between the connecting rods and the crankshaft, can wear down over time due to normal wear and tear or lack of lubrication. When the bearings become worn, they can no longer provide a smooth surface for the rods to move against, resulting in a knocking sound.

To extend the life of your engine with rod knock caused by worn bearings, there are a few things you can do. First and foremost, regular oil changes with high-quality synthetic oil is essential. This will ensure that the engine is properly lubricated and reduce friction on the bearing surfaces.

Additionally, using additives specifically designed to address noisy engines or worn bearings can be helpful. These additives work by providing extra cushioning and protection to minimize metal-to-metal contact. Monitoring your engine’s temperature is also important as excessive heat can accelerate bearing wear. Keeping an eye on coolant levels and ensuring proper cooling system maintenance will help prevent overheating.

If you suspect your engine has rod knock caused by worn bearings, it’s best to have it inspected by a professional mechanic who can accurately diagnose and recommend appropriate repairs or replacements. Remember that preventing further damage should always be a priority when dealing with rod knock caused by worn bearings!

2. Lean air to fuel mixture

One of the causes of rod knock in an engine is a lean air to fuel mixture. When there is not enough fuel being supplied to the combustion chamber, the engine runs hotter and increases the risk of knocking. This can happen for several reasons. A clogged or dirty fuel injector may not be allowing enough fuel to pass through, resulting in a lean mixture. Regular maintenance and cleaning of the injectors can help prevent this issue.

Another possible cause is a malfunctioning oxygen sensor, which measures the amount of oxygen in the exhaust gases and sends signals to adjust the air-fuel ratio accordingly. If this sensor is faulty or worn out, it can lead to incorrect readings and result in a lean mixture. Furthermore, an intake manifold leak can also contribute to a lean air-fuel mixture. If there are any cracks or gaps in the intake manifold gasket or seals, unmetered air can enter into the system causing an imbalance between air and fuel.

To address these issues and extend the life of your engine with rod knock caused by a lean air-fuel mixture, it’s important to regularly inspect and maintain your fuel injection system, including cleaning or replacing clogged injectors if necessary. Additionally, ensuring that all sensors are functioning properly by conducting regular diagnostic checks will help maintain proper air-fuel ratios.

3. Low octane

When the octane rating is too low, it causes premature ignition of the air-fuel mixture inside the combustion chamber. This leads to excessive pressure on the connecting rods, resulting in that distinctive knocking sound. Using low octane fuel not only affects engine performance but also increases the likelihood of damaging internal components. The detonation caused by low octane levels puts extra stress on the crankshaft bearings and piston rings, leading to accelerated wear and tear.

To prevent or mitigate rod knock caused by low octane fuel, it’s essential to use gasoline with a higher octane rating. Higher-octane fuels withstand compression better and resist spontaneous combustion, reducing the chances of pre-ignition. Regularly using fuel additives specifically designed for increasing octane levels can also help alleviate this issue. These additives improve combustion efficiency while reducing knocking tendencies.

Ensuring you use high-quality gasoline with an appropriate octane rating is crucial for extending the life of an engine with rod knock caused by low-octane fuel consumption. It’s always best to consult your vehicle manufacturer’s recommendations regarding proper fuel requirements as well.

4. Bad belt tensioners

One of the causes of rod knock in an engine is a bad belt tensioner. The belt tensioner is responsible for maintaining the proper tension on the engine’s belts, ensuring they operate smoothly and efficiently. When the belt tensioner becomes worn or damaged, it can lead to excessive vibration and movement of the belts, which can result in rod knock. A bad belt tensioner can also cause additional stress on other engine components, such as the crankshaft and connecting rods. This increased strain can lead to further damage and wear over time if left unaddressed.

To prevent or mitigate rod knock caused by a bad belt tensioner, regular maintenance and inspection are crucial. It is essential to check for any signs of wear or damage on the belt tensioner and replace it promptly if necessary. Additionally, ensuring that all belts are properly aligned and tightened will help reduce unnecessary stress on the engine. By addressing issues with a bad belt tensioner early on, you can extend the life of your engine and avoid more significant problems down the road. Regular maintenance and attention to detail are key when it comes to keeping your engine running smoothly despite having rod knock caused by a faulty belt tensioner.

5. Poor timing

Timing refers to the precise moment when the spark plug ignites the air-fuel mixture in each cylinder. If the timing is off, it can result in uneven combustion and increased stress on the connecting rods. There are several reasons why a car’s timing might be poor. One possibility is that the ignition timing is set incorrectly, which means that the spark plug fires either too early or too late. This can occur due to mechanical issues with the distributor or improper adjustment of the ignition system.

Another potential cause of poor timing is a malfunctioning camshaft position sensor. This sensor helps determine when to fire each spark plug based on information from the crankshaft position sensor and other inputs. If it fails, it can lead to incorrect timing and eventual rod knock. Additionally, worn timing belts or chains can also contribute to poor timing. These components help synchronize the rotation of various engine parts, including the camshafts and crankshaft. When they become stretched or damaged over time, they may not function properly and throw off engine timing.

To address poor timing and prevent further damage from rod knock, it’s essential to have your vehicle inspected by a qualified mechanic who can diagnose any underlying issues with your ignition system or related components. By identifying and resolving these problems promptly, you’ll help extend the life of your engine despite experiencing rod knock.

6. Bad knock sensor

One common cause of rod knock in an engine is a bad knock sensor. The knock sensor is responsible for detecting unusual vibrations or knocking sounds in the engine, which could indicate a problem with the connecting rods. When the knock sensor fails to function properly, it may not be able to detect these abnormal vibrations and therefore cannot alert the engine control unit (ECU) to make necessary adjustments.

A faulty knock sensor can lead to serious damage if left unaddressed. The ECU relies on this sensor to adjust ignition timing and fuel mixture for optimal performance and efficiency. Without accurate data from the knock sensor, the ECU may not be able to prevent excessive stress on the connecting rods, leading to rod bearing wear or even catastrophic failure.

If you suspect that your vehicle’s knock sensor is faulty, it’s important to have it diagnosed and replaced by a qualified mechanic as soon as possible. Ignoring this issue can significantly shorten your engine’s lifespan and increase the risk of further damage. Regular maintenance and inspections can help identify any issues with the knock sensor early on. This includes checking for any trouble codes related to knock detection during routine diagnostic scans.

A bad knock sensor can contribute to rod knocking in an engine if left unresolved. It is crucial to address this issue promptly through proper diagnosis and replacement by a professional mechanic in order to extend your engine’s life expectancy.

Tell me the best way to fix a rod knock?

When it comes to fixing a rod knock in your engine, there are a few options you can consider. However, it’s important to note that the best way to fix a rod knock will ultimately depend on the severity of the issue and the condition of your engine. One option is to replace the entire engine or rebuild it. This involves removing the damaged components and replacing them with new ones or repairing any worn-out parts. While this may be costly, it can provide a long-term solution and extend the life of your engine.

Another option is to repair or replace just the connecting rod bearing that is causing the knocking sound. This involves removing the oil pan, crankshaft, and connecting rods in order to access and replace the bearing. It’s important to have this done by a professional mechanic who has experience working with engines.

In some cases, using an additive specifically designed for addressing engine noise may help reduce or eliminate rod knock temporarily. These additives work by improving lubrication and reducing friction within the engine components. However, keep in mind that this is not a permanent solution and should only be used as a temporary fix until proper repairs can be made.

It’s worth mentioning that attempting DIY fixes without proper knowledge or experience can cause further damage to your engine. Therefore, consulting with a professional mechanic is always recommended when dealing with rod knock issues. Remember, each situation is unique and what works for one person may not work for another. Consulting with an expert will ensure that you receive tailored advice based on your specific circumstances.

What is rod knock?

Rod knock is a common engine problem that can have serious consequences if left unaddressed. Essentially, it refers to the knocking sound that occurs when the connecting rod bearings in an engine become worn or damaged. These bearings help to keep the crankshaft and piston rods properly aligned, but over time, they can wear down due to factors such as poor lubrication, high mileage, or excessive heat.

When the bearings wear down, they create a gap between the connecting rod and crankshaft. This causes increased play and allows for metal-on-metal contact, resulting in that distinctive knocking sound. If you hear this sound coming from your engine, it’s crucial not to ignore it.

Ignoring rod knock can lead to further damage within your engine. The excessive play between parts can cause additional stress on other components like pistons and cylinders, leading to more severe issues such as piston slap or even complete engine failure.

While some may be tempted to simply add thicker oil as a temporary fix for rod knock noise, this is not a recommended solution. Thicker oil may mask the noise temporarily by providing extra cushioning between moving parts but will not address the underlying issue of worn bearings.

Driving with rod knock is risky and could result in catastrophic engine failure if ignored for too long. It’s important to consult with a professional mechanic who specializes in diagnosing and repairing engine issues promptly. Understanding what rod knock is and recognizing its potential consequences are essential steps in extending the life of an engine experiencing this problem. Taking prompt action through proper diagnosis and repair by a qualified mechanic is crucial for preventing further damage and ensuring optimal performance of your vehicle’s engine.

Is it safe to drive with a rod knock?

This is a question that many car owners may find themselves asking when faced with this issue. The answer, however, is not as straightforward as one might hope.

Rod knock refers to the knocking sound that occurs when the connecting rod bearings in the engine become worn or damaged. This can happen due to various reasons such as lack of lubrication, excessive heat, or metal fatigue. When these bearings wear out, they can cause the connecting rod to come into contact with other engine components, resulting in that distinctive knocking noise.

Driving with a rod knock is generally not recommended. While you may be able to continue driving for a short period of time without experiencing any catastrophic failure, doing so can lead to further damage and potentially even complete engine failure.

Continuing to drive with a rod knock puts additional stress on the already compromised bearings and can cause them to fail completely. This can result in severe engine damage, including bent rods or holes in the engine block. In addition, driving with a rod knock can also affect other parts of your vehicle’s system. The increased vibrations caused by the knocking can put strain on other components like motor mounts or suspension elements.

If you notice any signs of a rod knock – such as loud knocking noises coming from your engine – it’s best to have your vehicle inspected by a professional mechanic right away. They will be able to assess the extent of the damage and provide guidance on how best to proceed.

Remember that taking immediate action when you suspect an issue will help extend the life of your engine and prevent further complications down the road. So don’t ignore those strange sounds coming from under your hood – get them checked out sooner rather than later!

What damage happens due to the rod knock?

When it comes to rod knock, the damage can be quite severe. This knocking noise is a telltale sign that something is seriously wrong with your engine. But what exactly happens when you have a rod knock? First and foremost, the connecting rods in your engine are responsible for transferring power from the pistons to the crankshaft. When these rods become worn or damaged, they can start to knock against the crankshaft, causing that dreaded sound.

As this knocking persists, it can lead to even more significant issues. For starters, excessive wear on the bearings can occur as a result of the constant impact between the rods and crankshaft. Over time, this wear can cause metal shavings and debris to circulate throughout your engine’s oil system.

Furthermore, if left unaddressed for too long, rod knock can eventually result in catastrophic engine failure. The continued stress on other components like piston rings and cylinder walls may lead to further damage or complete breakdown. In addition to these mechanical consequences, driving with a rod knock also puts you at risk of expensive repairs or having to replace your entire engine altogether.

Can thicker oil stop engine knocking?

This is a common question among car owners who are dealing with rod knock. While some people believe that using thicker oil can help alleviate the problem, it’s important to understand how engine knocking occurs and whether thicker oil is an effective solution.

Engine knocking, also known as detonation or spark knock, happens when the air-fuel mixture in the combustion chamber ignites prematurely. This causes a knocking or pinging sound and can lead to serious damage if not addressed promptly. One of the main causes of this issue is low-quality fuel or incorrect ignition timing.

Thicker oil might seem like a logical fix because it increases viscosity and provides better lubrication for moving parts. However, it may not necessarily solve the underlying issue causing the rod knock. In fact, using excessively thick oil can potentially restrict proper lubrication flow and cause other problems in your engine.

If you’re experiencing rod knock, it’s best to consult with a professional mechanic who can diagnose the root cause of the issue. They will be able to provide appropriate recommendations for fixing your specific problem rather than relying on generic solutions like using thicker oil.

While heavier weight oils may offer temporary relief from engine knocking symptoms by providing additional cushioning between metal surfaces, they are not a permanent solution for addressing rod knock issues. It’s essential to address any underlying problems causing the rod knock rather than relying solely on thicker oil as a remedy.

How to extend life of an engine with rod knock?

1. Replace the bearings

One crucial step in extending the life of an engine with rod knock is to replace the bearings. Rod knock occurs when there is excessive wear and tear on the connecting rod bearings, causing them to become loose or damaged. These bearings play a vital role in maintaining proper alignment and reducing friction between moving parts. When replacing the bearings, it’s essential to choose high-quality ones that are specifically designed for your engine model. Low-quality or incompatible bearings can lead to further damage and shorten the lifespan of your engine.

To replace the bearings, start by draining the oil from your engine and removing any necessary components to access them. Carefully remove the old bearings using specialized tools, making sure not to scratch or damage other parts during this process. Once removed, thoroughly clean all surfaces before installing new bearings. Apply a thin layer of lubricant on both sides of each bearing before carefully fitting them into place. Be cautious not to overtighten as this can cause premature wear.

After replacing the bearings, refill your engine with fresh oil and check for any leaks or abnormal noises during startup. Regularly monitor oil levels and perform routine maintenance tasks like oil changes at recommended intervals. By promptly addressing rod knock through bearing replacement, you can help extend the life of your engine and prevent more significant issues down the road. Remember that early detection and proactive maintenance are key when dealing with rod knock!

2. Replace connector rods

Replacing the connector rods is another important step in extending the life of an engine with rod knock. The connector rods, also known as connecting rods or conrods, play a crucial role in transferring motion from the piston to the crankshaft. Over time, these rods can wear out or become damaged due to excessive stress or lack of lubrication. When replacing the connector rods, it’s essential to choose high-quality replacement parts that are compatible with your specific engine model. It’s recommended to consult with a professional mechanic or refer to your vehicle’s manual for guidance on selecting the right parts.

The process of replacing the connector rods involves removing various components such as pistons and cylinder heads. This task requires careful precision and attention to detail, so it is generally best left to experienced mechanics who have the necessary tools and expertise. By replacing worn-out or damaged connector rods promptly, you can ensure proper engine function and prevent further damage caused by rod knock. Regular maintenance and inspection of these components will help prolong your engine’s lifespan and keep it running smoothly for years to come.

3. Check the coolant level

One crucial aspect of extending the life of an engine with rod knock is to regularly check the coolant level. The coolant plays a vital role in keeping the engine cool and preventing overheating, which can further damage the rods and other components. To ensure optimal performance, it’s important to maintain the proper amount of coolant in your vehicle at all times. Start by locating the coolant reservoir, often marked with a cap that has “coolant” or “antifreeze” written on it. Remove the cap and visually inspect the fluid level.

If you notice that the coolant level is low, add a mixture of equal parts water and antifreeze until it reaches the appropriate mark. It’s essential to use distilled water instead of tap water as tap water contains minerals that can cause corrosion over time. Regularly checking your vehicle’s coolant level will not only help prevent rod knock but also improve overall engine performance. So make sure to incorporate this simple yet effective maintenance task into your routine!

4. Use better quality lubricants

One important way to extend the life of an engine with rod knock is by using better quality lubricants. The lubricant plays a crucial role in reducing friction and heat within the engine, which can help prevent further damage to the connecting rods and bearings.

When it comes to choosing lubricants, opt for high-quality oils that are specifically designed for your vehicle’s engine type. These oils contain additives that provide better protection against wear and tear, ensuring smooth operation of the moving parts. Regular oil changes are also necessary to maintain optimal engine performance. Over time, oil breaks down and loses its ability to effectively lubricate the engine components. By adhering to a regular maintenance schedule and using high-quality lubricants, you can minimize wear on the rods and bearings.

Additionally, consider using synthetic oils as they offer improved viscosity stability across a wide range of temperatures. This means that even during extreme weather conditions, such as hot summers or cold winters, your engine will be well-lubricated. Remember that not all lubricants are created equal. Investing in better quality products may cost slightly more upfront but can potentially save you from costly repairs down the line. So make sure to choose wisely when it comes to selecting lubricants for your engine!

5. Replace bad spark plugs

One of the key components in an engine’s ignition system is the spark plug. It plays a vital role in igniting the air-fuel mixture inside the combustion chamber. Over time, spark plugs can become worn out or fouled, causing them to misfire and negatively impact engine performance. When you have a rod knock issue, it becomes even more crucial to replace bad spark plugs promptly. A worn-out or faulty spark plug can lead to inefficient fuel combustion, resulting in increased stress on your engine’s connecting rods and bearings.

To avoid further damage and extend the life of your engine with rod knock, make sure to inspect your spark plugs regularly for signs of wear or deposits. If you notice any abnormality such as erosion on the electrode tip or excessive carbon buildup, it’s time for a replacement. Investing in high-quality spark plugs specifically designed for your vehicle model is essential. These will provide optimal combustion efficiency while minimizing strain on other engine components.

Remember that replacing bad spark plugs not only improves overall engine performance but also helps maintain proper fuel economy and reduces harmful emissions from your vehicle. By addressing this simple maintenance task, you can play a significant role in extending the life of an engine affected by rod knock. Stay proactive and keep those sparks firing efficiently!

6. Do not overload

One of the key factors in extending the life of an engine with rod knock is to avoid overloading it. Excessive load on the engine can put undue stress on various components, including the connecting rods and bearings, which can accelerate wear and contribute to rod knock.

When you overload your engine, it has to work harder than it’s designed for, leading to increased friction and heat generation. This can cause damage to critical parts, such as piston rings and cylinder walls, ultimately resulting in a loss of performance and efficiency. To prevent overloading your engine, make sure you are aware of its maximum weight capacity for towing or carrying cargo. Avoid pushing your vehicle beyond its limits by distributing weight evenly and avoiding excessive acceleration or sudden braking.

Regular maintenance plays a crucial role here too. Keep an eye on fluid levels such as oil and coolant, ensuring they are at optimal levels for proper lubrication and cooling. Remember that prevention is always better than cure when it comes to prolonging the life of an engine with rod knock. By taking these precautions seriously, you’ll be able to minimize strain on your engine and maximize its longevity.

7. Replace the piston rod

Replacing the piston rod is a crucial step in extending the life of an engine with rod knock. The piston rod plays a vital role in connecting the piston to the crankshaft, allowing for proper movement and power transfer within the engine. Over time, the constant wear and tear on the piston rod can lead to damage and increased friction, which can contribute to further complications with rod knock. By replacing the worn-out or damaged piston rod, you can restore proper functionality and reduce strain on other components of your engine.

When replacing the piston rod, it’s important to ensure that you choose a high-quality replacement part that is compatible with your specific engine model. Additionally, it’s recommended to seek assistance from a professional mechanic who has experience in working with engines affected by rod knock. By addressing issues related to the piston rod promptly, you can prevent further damage from occurring and extend the overall lifespan of your engine. Remember that regular maintenance and care are key factors in keeping your engine running smoothly for years to come!

Final thoughts

In this article, we have discussed several ways to extend the life of an engine with rod knock. By following these steps, you can potentially save yourself from costly repairs or even having to replace your engine altogether. It is important to remember that addressing rod knock as soon as it is detected is crucial. Ignoring the problem and continuing to drive your vehicle can lead to severe damage and further complications.

Replacing the bearings and connector rods should be a priority if you want to prolong your engine’s lifespan. Additionally, keeping an eye on coolant levels, using high-quality lubricants, and replacing faulty spark plugs are all essential maintenance tasks. Furthermore, overloading your vehicle can put unnecessary strain on the engine components, so it is best to avoid exceeding its maximum capacity whenever possible. If rod knock persists despite taking these measures, it may be necessary to replace the piston rods. This should only be done by a professional mechanic who can ensure proper installation and alignment.

Remember that prevention is always better than cure when it comes to maintaining a healthy engine. Regularly servicing your vehicle according to manufacturer guidelines will help identify potential issues early on and allow for timely repairs. By implementing these tips into your routine maintenance schedule, you can significantly extend the life of an engine experiencing rod knock. Take care of your car’s heart – its engine – and it will reward you with many more miles of smooth operation! So don’t wait until it’s too late; start taking action today! Your wallet (and peace of mind) will thank you later.